Fastest and most efficient and accurate mounting machine in the world. Real-time video

The video above illustrates how the Automatic Mounting Machine SAMM 2.0 mounts 3 plates within 4 minutes, including a sleeve change. While the machine mounts, an operator demounts the plates from 4 sleeves with the Demounter.

The mounting process is very simple. The operator selects the job and roughly positions the plate. After, the plate is locked by the pressure roller and scanned for the registered marks, using our patented image recognition. Then the Automatic Mounting Machine the SAMM 2.0 automatically mounts plates using the motorized front table. At the end of the mounting process, the machine generates a pdf quality report which provides a full insight on the mounting results, ensuring full confidence before going to press. Thus, while the machine mounts each plate, the operator can simultaneously perform another task such as preparing the next plate, demounting plates or finishing an operation.

BENEFITS OF AUTOMATIC MOUNTING WITH THE SAMM 2.0

With the change in the printing industry, where lead times are shorter and job runs more frequent, the workflow for operating the SAMM 2.0 was updated, which bring following advantages:

UNIQUE FEATURES OF THE AUTOMATIC MOUNTING MACHINE THE SAMM 2.0

The automatic mounting machine the SAMM 2.0 is very versatile and has many options available such as a nip-roll assisted tape applicator, TIR scanning device and cutting knives for plates or tape. Besides, the machine is standardly equipped with unique features, which are mentioned below:

Image Recognition Software

The image recognition system measures the exact position of the mounting marks and thus how accurately the printing plate is fixed on the sleeve. The tolerance of the report settings determines whether a plate is judged as mounted “OK” or “NOT OK”.

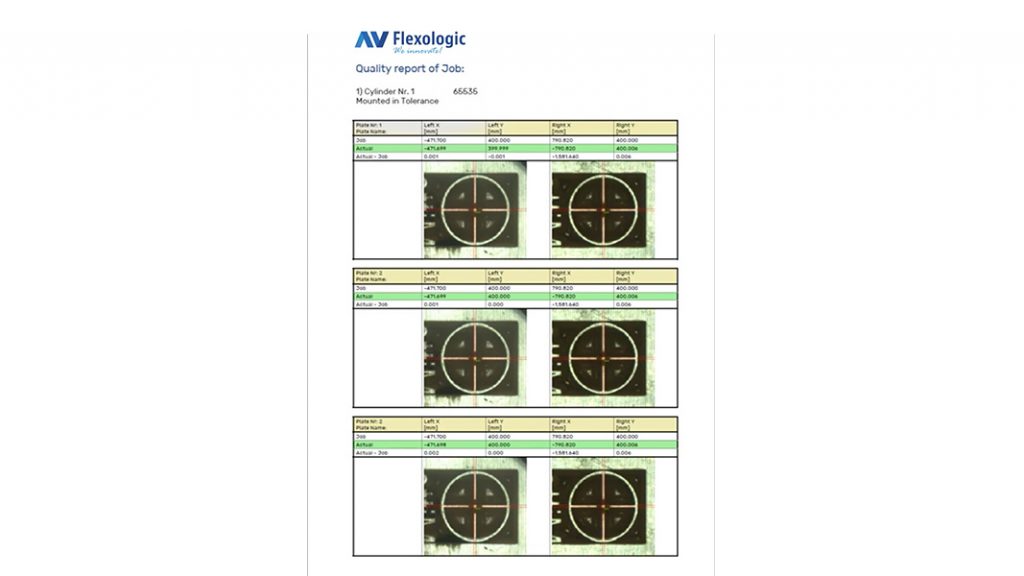

Quality Report

After each plate is mounted, the SAMM has the ability to automatically check the tolerance of mounting plates using image recognition. A pdf quality report is generated on-the-fly with ability to check top and bottom. It provides a full insight on the mounting results, ensuring full confidence before going to press.

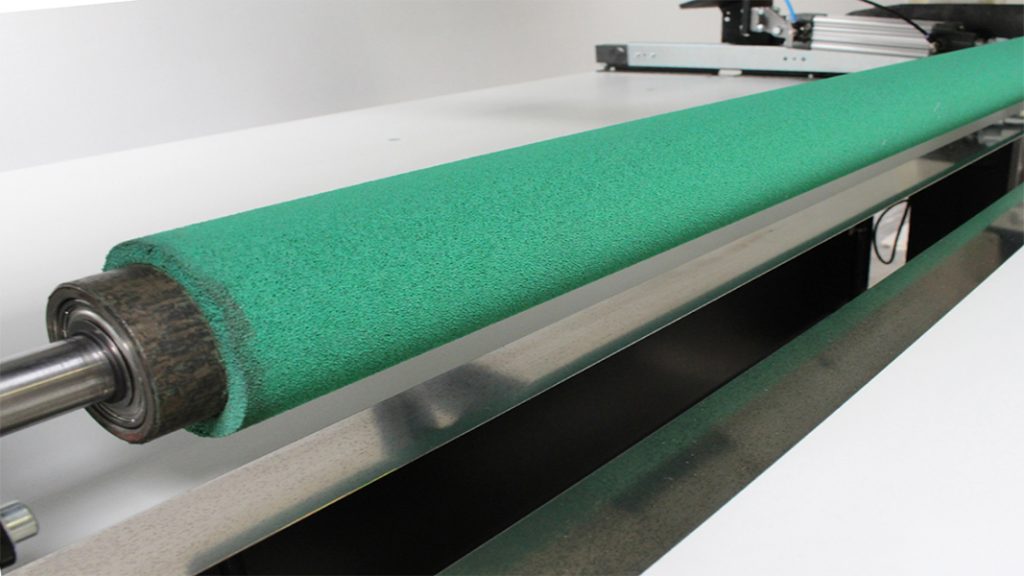

Pressure Roller

The pressure roller has become a standard feature in AV Flexologic flexo plate mounting machines over recent years. The roller is used to apply the plates evenly over carrier such as sleeve or cylinder. The use of the pressure roller eliminates the typical “hand-rolling”. The feature saves time and avoids un-ergonomic working procedures.

Laser pointers

Laser pointers are mounted next to the cameras to indicate where the field of view of cameras is. The mounting marks can be easily positioned in a fraction of time, instead of having to search for the mounting marks in the camera image each time.

If you would like to request an offer, please contact us. For more information about the machine visit our product page.